Recently, nearly all leading air conditioner manufacturers—including Gree, Midea, Haier, and Xiaomi—jointly signed a self-discipline convention aimed at promoting the replacement of copper with aluminum in air-conditioner heat exchangers. A materials revolution sweeping through the air-conditioning industry has officially begun. Coincidentally, a similar transformation is now gaining momentum in the new energy vehicle (NEV) motor industry as well.

As price competition in the new energy sector intensifies and copper prices continue to rise, the industry’s demand for cost reduction is becoming increasingly urgent. Thanks to its lower cost and lighter weight, aluminum wire is gradually attracting greater attention. Companies such as BorgWarner and UAES have already begun developing aluminum-wire motors to replace copper-wire motors in specific application scenarios.

At present, hair-pin motors have not yet been widely adopted in auxiliary motors for new energy vehicles. The main reason lies in the remaining challenges of mass-production processes for aluminum-wire stators. Compared with copper wire, aluminum wire is more difficult to straighten, forming, and twisting, posing higher manufacturing demands.

The most challenging process in aluminum-wire motor stator manufacturing, however, is aluminum-wire stator welding. Aluminum wire oxidizes more easily than copper, and aluminum oxide is extremely dense and electrically insulating, which can easily lead to poor electrical conductivity during welding. In addition, molten aluminum has high fluidity and tends to flow to both sides during welding, resulting in incomplete fusion between welded segments. Furthermore, noticeable collapse often occurs at the top of the weld ball during the welding process.

Nevertheless, as a pioneer in cutting-edge industry technologies, NEVEM has successfully overcome these technical challenges through continuous innovation. The company now possesses the capability to design and manufacture mass-production lines for aluminum-wire motors, and can provide customers with ready-to-deploy, application-level solutions at any time.

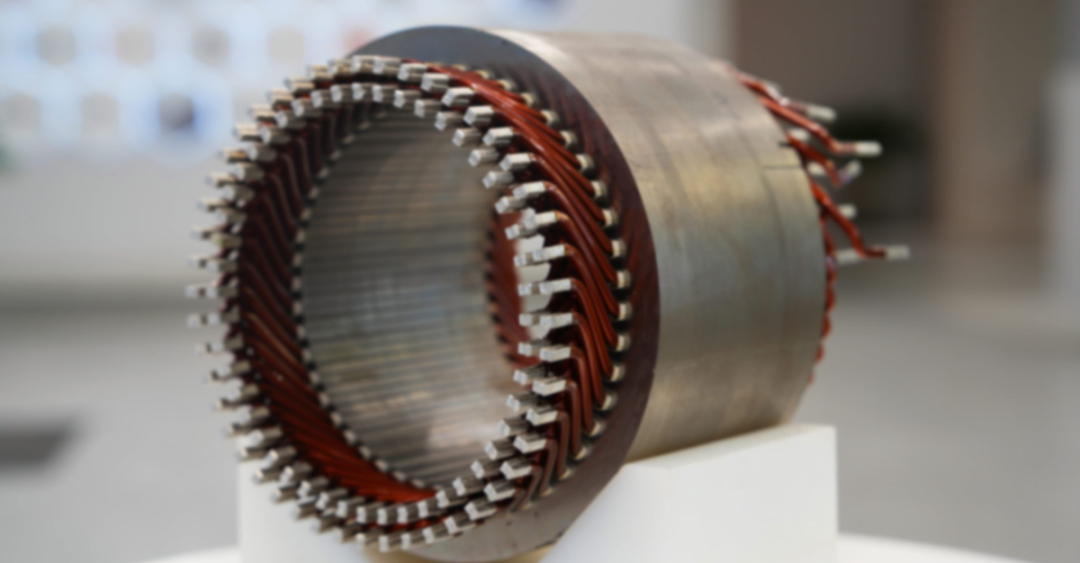

NEVEM Aluminum-Wire Stator Demonstration:

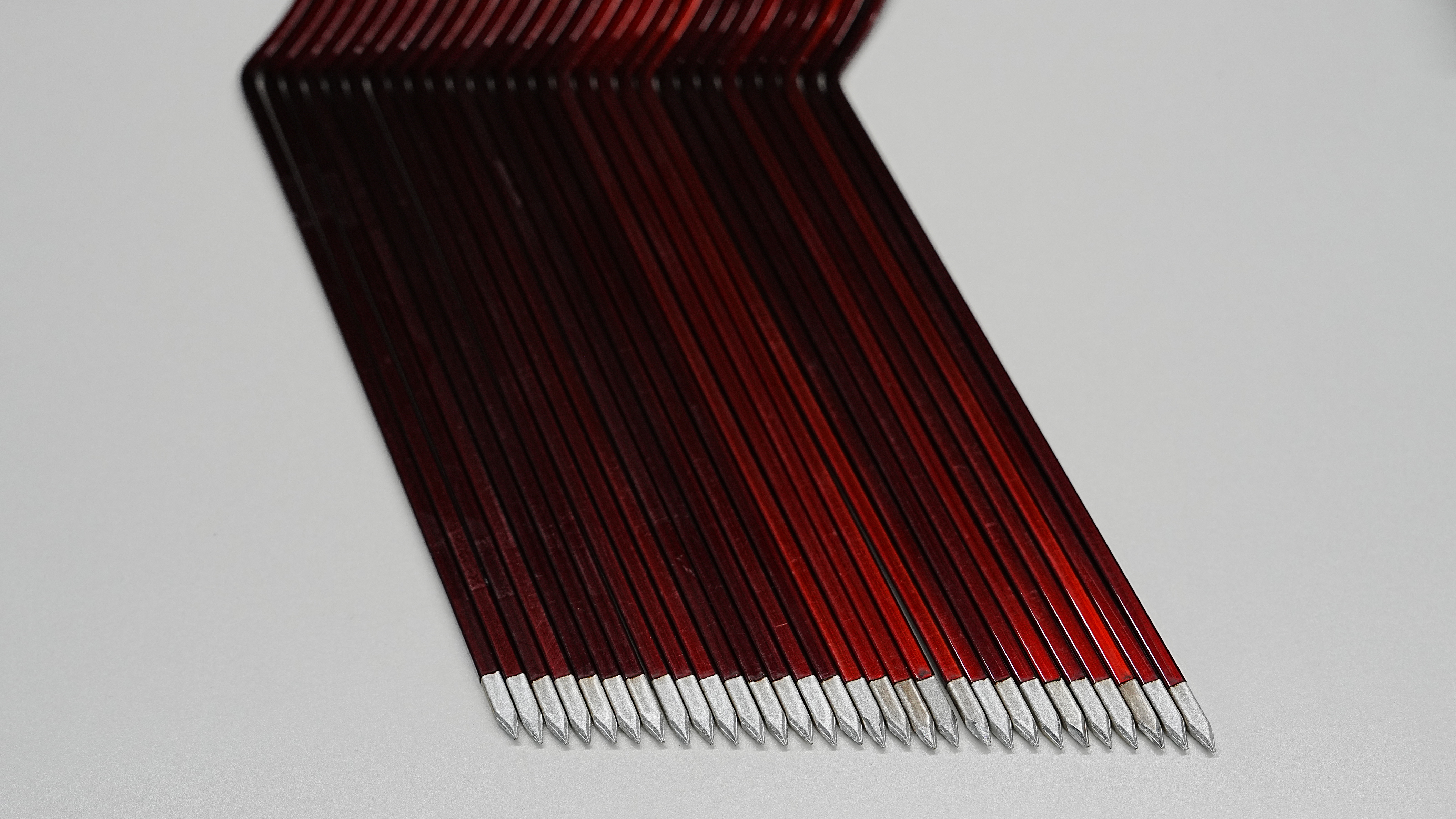

Detailed display of 5 mm Mini-Pin aluminum-wire welding, featuring smooth and aesthetically pleasing weld joints:

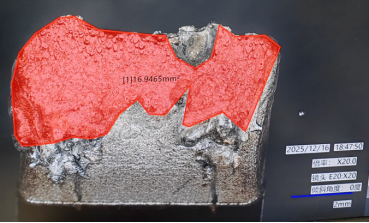

Pull-out force tests of aluminum-wire welds, all reaching the same performance level as copper-wire welds:

The fusion area of 5 mm Mini-Pin aluminum wire reaches 15–16 mm², with a fusion ratio exceeding 100%, representing an excellent industry benchmark:

Driving industry advancement through technological innovation has always been a core commitment of NEVEM. In flat-wire motor processes, building upon traditional Hair-Pin technology, we have introduced Mini-Pin and X-Pin stator mass-production processes, both of which have already been applied in customer projects, accelerating process evolution across the industry.

In terms of conductor materials, beyond mainstream copper windings, we have also developed aluminum-wire windings and hybrid winding technologies, helping customers reduce costs while maintaining competitive advantages in an increasingly fierce market.

Looking ahead, NEVEM will continue to uphold its innovation-driven philosophy, create greater value for customers, and contribute to the high-quality development of the industry.